Answers for the Glass Industry

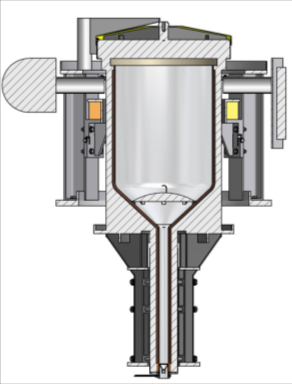

Special Melting Facilities

- Platinum melter

- Specific day tanks

- Induction heated furnaces

- Crucible melting facilities

- Pot furnaces

Chemical Strengthening of Glass

Our chemical strengthening lines

are noted for their

- functioning and robustness

- low energy consumption

- high degree of automation

- ease of operation

- low maintenance cost

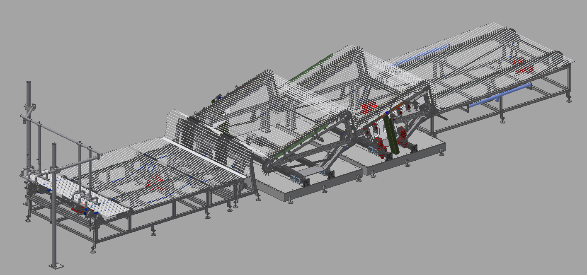

Heat Treatment Equipment

- Belt tempering lines

- Spindle type tempering lines

- Rim tempering machines

- Specific bending furnaces

- Ceramizing ovens

- Custom-designed special lehrs

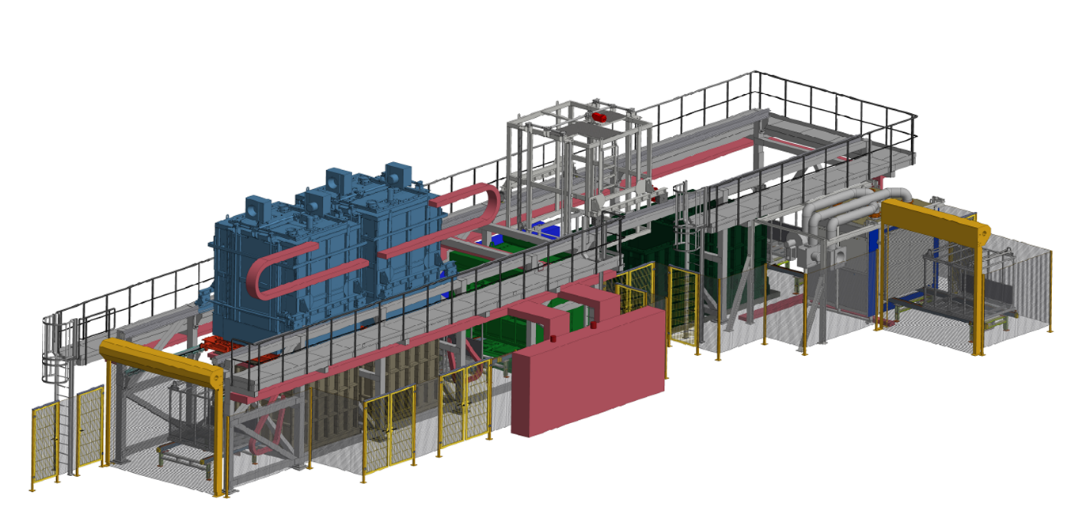

Tube Drawing Lines

- Danner, Vello-, Down draw process

- Production of tubes, capillaries, rods (<1 mm – 400 mm)

- High quality tubes for pharmaceutical packaging

- Lines for borosilicate, lead, soda lime, and alumosilicate glass

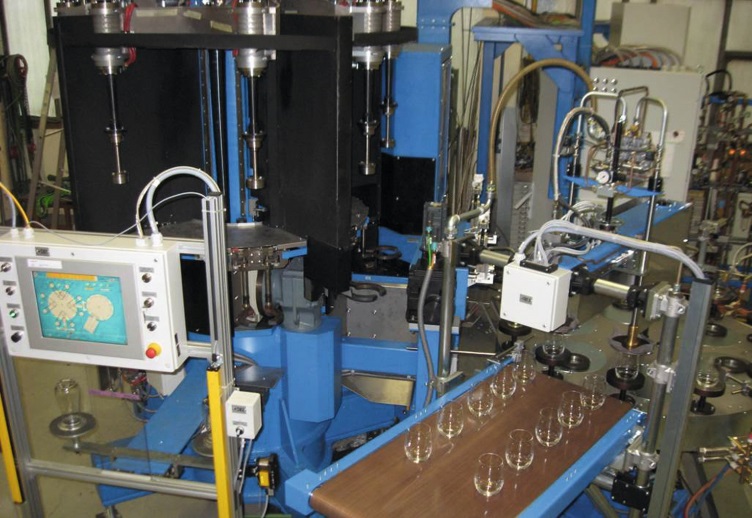

Glass Blow Production Lines

- Forming machines

- Transport and handling

- Annealing and tempering

- Processing

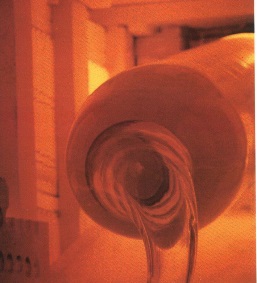

Laser Machinery Systems

- Laser hot cutting of blow products

- Laser hot cutting of tubes

- Laser bending of thin glass

- Laser welding

- Laser cutting of flat glass

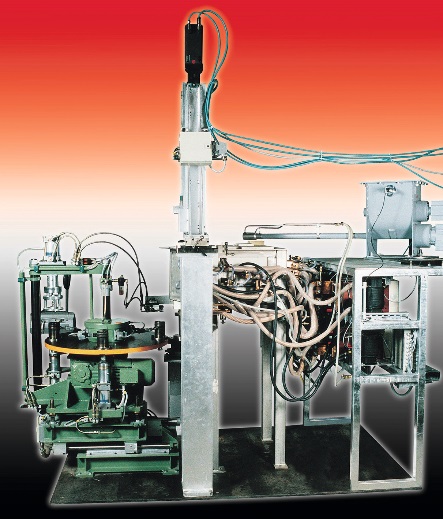

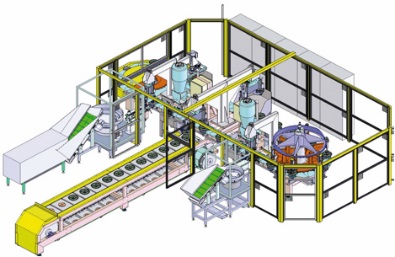

Special Machinery

- Specific forming and casting equipment

- Batch charging machines

- High precision feeder mechanisms

- Processing equipment

- Transport and handling equipment

- Special machines on customer request

Special Machinery / Non Glass

Development, planning, construction of custom-designed machines for

- aircraft industry

- solar industry

- electronic industry

- automotive industry

- pharmaceutical industry

- medical industry

Technical Center

- Glass melting services

- Melting tests and raw material assessments

- Melting technology investigations

- Measurement of physical properties of glass melts (el. conductivity, viscosity)

- Corrosion tests (refractory and electrode materials)

- Glass production on customer request

- Test facilities for chemical strengthening

- Laser hot cutting test station

- Laser bending test facility